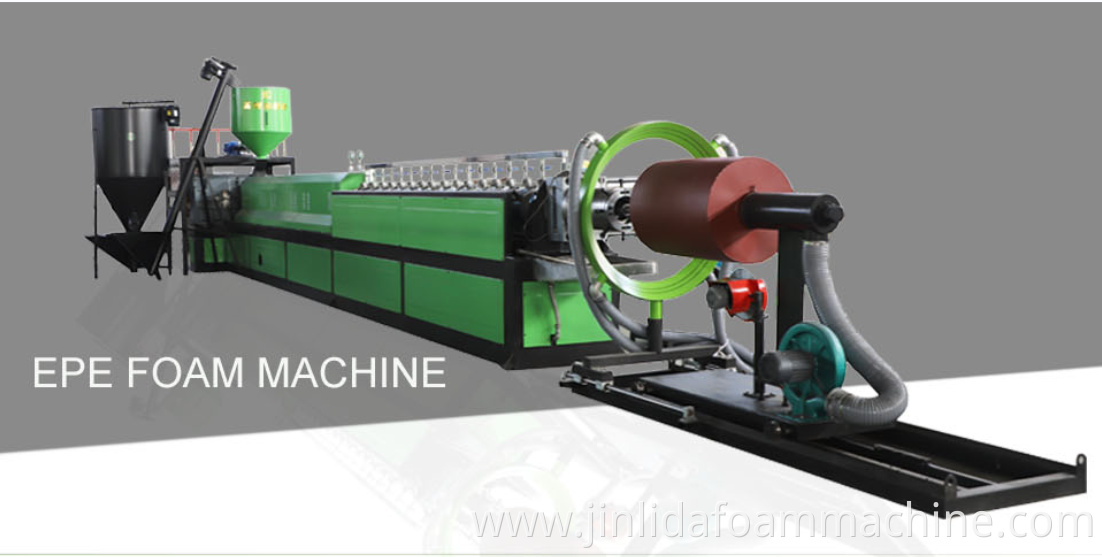

high quality EPE foam sheet extrusion machine

PE Foam Sheet Extruder, EPE Foam Sheet Extruder produces closed find cell Polyethylene foam sheet by our unique designed Screw and Barrel system using Butane, Talc master batch and GMS(Surface Active Agent) by accumulated experience and advanced technology.

PARAMETER LIST

| Mode1 Sheet Width Thickness Capacity | Screw Diameter | Installed Dimension Weight Power |

| EPE-75 | 850-1200mm | 0.3-2mm | 25-50kg/h | 75mm | 50kW | 20x4x3m | 5 tons |

| EPE-90 850-1500mm 0.3-5mm 60-90kg/h 90mm 80kW 22x4x3m 7.5 tons |

| EPE-105 | 850-2700mm | 0.3-6mm | 80-120kg/h | 105mm | 95kW | 25x4x3m | 8.5 tons |

| EPE-120 900-4000mm 0.5-7mm 120-180kg/h 120mm 115kW 27x4x3m 9.5 tons |

| EPE-135 | 900-4000mm | 1-10mm | 170-240kg/h | 135mm | 145kW | 35x4x3m | 10.5 tons |

| EPE-150 900-4000mm 2.5-12m m 250-300kg/h 150mm 270kW 38x7x3m 11 tons |

| EPE-180 | 1000-4000mm | 3-14mm | 300-400kg/h | 180mm | 310kW | 41x7x3m | 13 tons |

| EPE-200 1000-4000mm 3-18mm 400-550kg/h 200mm 400kW 42x7x3m 15 tons |

| EPE-220 | 1000-4000mm | 4-22mm | 600-700kg/h | 220mm | 450kW | 45x7x3m | 18 tons |

| EPE-2501000-4000mm 4-25mm 700-800kg/h 250mm 510kW 50x7x3m 22 tons |

| Note | If you don't know how to choose the machine model,please tell us your requirement of the epe foam that you will make, then we can help you. |

Applications:

1. Characteristics Of Product

High resilience and buoyant effect.

Effective insulating capability.

Low thermal conductivity.

Negligent absorption and water permeability.

Chemical Resistant.

Effective and safe to handle in installation application.

Non-toxic and environmental friendly : free of CFC, HCFC.

Fine round closed-cell cellular structure assures.

Excellent flexibility.

100% Recyclable and Reusable.

2. Applications Of Product

External cushioning and packing material.

Packaging for high-grade goods, industrial electronic parts.

Construction materials for insulation.

Educational materials.

EPE has good resilience, it is a waterproof material, it is also a thermal insulation material, and it is also a sound insulation material. It is versatile and is mainly used in the packaging industry. Such as packaging to protect fragile glass products, electronic products, aluminum alloy doors and windows, wooden furniture, etc. It is also commonly used as floor protection material. Can also be used to make mattresses. The most popular product is the children's play mat.

EPE MACHINERY MANUFACTURE

WE FACTORY ESTABLISHED IN 2003.WE ONLY FOCUS ON EPE MACHINERY.SO THAT WE ARE ONE OF THE BEST EPE MACHINE SUPPLIER.

If you need more information, please feel free to contact me

Q:Why I choose your company?

A: a, We are China Leading foam machine Manufacturer. b, our company have made foam machine about 18years with strong experience and advanced technics c, Best Quality & Best Service with Competitive price. d, 100% inspection Before Shipment. And we have got CE certificate100% e, we have Professional technical team, will supply 24 hours service f, our machine have good quality, 1 year guarantee Other machines produced by us 1. EPE Foam Machine: This machine is used to produce expanded polyethylene (EPE) foam. It utilizes a heating and cooling process to expand and shape the foam material into various forms and sizes.

2. EPE Bonding Machine: This machine is designed for bonding or laminating multiple layers of EPE foam together. It uses heat and pressure to melt and fuse the foam layers, creating a strong and durable bond.

3. Extruding Laminating Machine: This machine combines the processes of extrusion and lamination to produce a composite material. It extrudes molten plastic onto a substrate, such as EPE foam, and then laminates another layer onto it, resulting in a finished product with enhanced strength and functionality.

4. EPE Recycling Machine: This machine is used for recycling and reprocessing waste or scrap EPE foam. It crushes and granulates the foam into smaller particles, which can then be reprocessed and used for various applications.

5. Auto Cutting Machine: This machine is designed to automatically cut EPE foam into desired shapes and sizes. It utilizes computer-controlled precision cutting technology to ensure accurate and efficient cutting.

6. Baby Mat Making Machines: These machines are specifically designed for manufacturing baby mats using EPE foam. They include various processes such as foam extrusion, bonding, laminating, and cutting to produce soft and safe mats for babies to play or rest on.